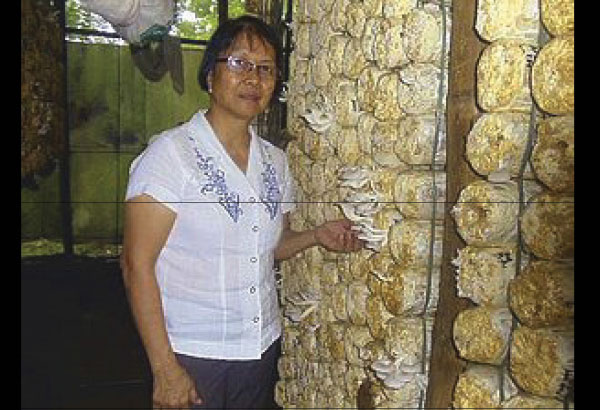

MANILA, Philippines - Mushroom production has long been an industry here in the Philippines. This technology gained popularity among farmers and food enthusiasts due to its social, economic and environmental impact. With this, the Laguna State Polytechnic University (LSPU) has engaged itself in the production of oyster mushroom through the initiatives of Lolita Viyar, a professor of the College of Agriculture in Siniloan Campus and the support given by the university administration headed by Nestor de Vera, LSPU president.

According to Viyar, the production of oyster mushroom started as a laboratory exercise of her students in the Bachelor of Science in Agriculture program. They were doing hands-on procedures on the production of pure culture, spawn grains up to the preparation of substrates when the idea of having a mushroom project came to her mind and thereafter started pursuing her concept.

The project officially commenced after the approval of her project proposal on the setting up of oyster mushroom production in LSPU, Siniloan campus. The potential of the proposal was recognized by the LSPU administration and gained fund support for the construction of one growing house.

During the implementation of the project, sawdust from the furniture and woodcarving shops in the municipality of Paete, a town famous for its wood carving, was used as the main ingredient in the preparation of substrates for the oyster mushroom. Pure culture or mother culture of mushroom was prepared using a prototype isolation chamber. This was used to pursue the project despite the limitation of laboratory facilities and equipment during project’s early stages.

Before producing fresh oyster mushroom, various step-by-step procedures divided into four phases were done.

First, mother culture and spawn grains were prepared. A small tissue of oyster mushroom was inoculated into prepared PDA or potato dextrose agar. This was incubated to allow the growth of the mycelia on the top of the media. After one to two weeks of incubation, a small cut of the pure culture was transferred or inoculated into a bottle containing sterilized grain like sorghum or corn to multiply the culture and for easier inoculation into the substrate bags.

Second was the preparation of substrate bags. Sawdust from Paete wood carvers was mixed with other ingredients like lime and rice bran in a proportionate ratio. The mixture was placed in a polypropylene bag and pasteurized by steaming.

Third, the prepared spawn grain was further inoculated into the steamed bags in a clean and sanitized room. This was then incubated for about 15 to 20 days before hanging in the growing house.

Fourth, the growing house was always maintained to be clean in order to avoid contamination of fruiting bags. Regular watering was done to maintain moisture in the bags for the growth and development of oyster mushroom.

Presently, the project is producing five to 10 kilograms per day with a selling price of P100 per kilogram. These are sold to faculty members and personnel of the university and to the local market of Siniloan. A total of 2,000 fruiting bags are prepared every month.

On the other hand, to promote the product, the team of Viyar joined various product exhibits in the municipal and regional levels. With this endeavor, the demand for oyster mushroom tremendously increased that there are times that they can not satisfy the demand.

According to Viyar, the supply of oyster mushroom is very minimal at present and this necessitates expansion of the production capacity of the project since there is an indication of increasing demand in the locality.

Focusing on the four-fold function of the university, the concept of LSPU in producing oyster mushroom is to share the technology with the community through their extension service. In coordination with local government units, setting-up of oyster mushroom production enterprises in different areas in the municipality and neighboring towns has been initiated. This endeavor is greatly believe to generate livelihood activities for the communities.

With the question on what will happen to the harvest of partner communities if all of them will produce oyster mushroom, Viyar optimistically explained that the project does not only focus on production of fresh oyster mushroom. Other components of the project will develop different products that will utilize the harvest. Products such as mushroom tempura, kropek, pasta, chips and by products were already being addressed by the team.

Other research and development activities conducted include the evaluation of the performance of Pluerotus sp. on different agricultural wastes like banana leaves and stalks, sugarcane bagasse, rice straw and others. Search for alternative grains for sorghum seeds as substrate for the multiplication of spawn was also undertaken.

Besides oyster mushroom, Viyar is also working on the production of other mushroom species like shiitake mushroom, button mushroom and milky mushroom, all of which have high market values. Other than the production aspect, the utilization of “used up” or spent mushroom substrates were evaluated for their efficacy as bio-fertilizer and substrates in vermi-composting.

In their effort to intensify mushroom production and utilization, Viyar’s team in coordination with the university’s Research and Development Office is planning to establish demonstration farms in strategic areas in Laguna. This will serve as show windows for the technology and boost the production of oyster mushroom, thereby helping generate additional livelihood enterprises in rural communities and hopefully make Laguna as the mushroom capital of the country.

Furthermore, the technology and the ability of Pleurotus sp has a great impact in turning a bulk of agriculture and industrial waste into opportunities, Viyar says.