From lab to fab

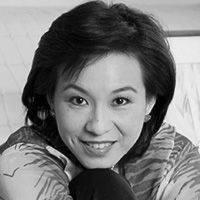

Catchy name, this “lab to fab” buzz-phrase, according to Celia Elumba, director of the Philippine Textile Research Institute (PTRI), is the new shift in direction for the approach to her work at the institute.

Barely less than a year into her position, this dynamic woman has shaken and awakened the sleepy research institution to move research knowledge into practical applications.

From basic R&D technical training services, says Celia, the PTRI is now moving to that “of applied research, of a developmental nature that has a predetermined application at the end of the process.”

“FAB is an acronym for Fabric Applications and Beyond. The research work we do extends to other applications, be it in nano and bio-nano technology, the health sciences and other textile-related areas. It is our aim to make the research work both technologically-sound and economically-viable,” she emphatically says.

She called me out of the blue for a meeting. “We need people like you, the social entrepreneurs to hold hands with us,” was her first statement to me. I was hooked. Only because I love working with dynamic people who set their eyes on big goals that would benefit many. And also because here was someone who could see the strength of what collaborations can do. She knew I am involved in trying to make some sense of the natural fibers and textiles needed by our ECHOsi Foundation and ECHOstore community groups for weaving.

The majority of our local women weavers just resort to buying China-made textiles and use them for embroidery, or weave using rayon and synthetic fibers like polyester. Textile producers and fashion designers and retailers resort to importing textiles because we don’t have a robust local industry. The country has had no substantial commercial textile exportation in the past couple of decades. Export competitiveness becomes the measure of how we can withstand competition with imports for our domestic market specific. With the ASEAN integration coming into play, we may soon be Filipinos dressed in Indian cotton, Thai silk or Chinese synthetic polyester and nylon (if we are not already). Meanwhile, beyond all the export goals, we do have 100 million Filipinos to dress up.

Locally, we have hand-weaving communities and a knit fiber sector. PTRI wishes to address the supply gap of yarns and yarn blends coming from fiber sources indigenous to the country. Celia says, “We look to integrate the supply and value chains, localizing value-addition and building design into the process so that the weavers will be producing with a product and market or consumer in mind. For this, we look to resources — whether for fiber to yarn production or plants for dye extraction and which can be used to add more value to the product — that are natural to the environs.”

Celia’s vision for the PTRI stems from her self-avowed social development advocacies with an interest in the practical applications of work across various disciplines particularly where social science meets business. And her track record of linking social development, to business and marketing is a lifetime career that started when she finished a Bachelor of Science in Clothing Technology degree from UP. Her career path included foreign liaison, sourcing, operations, merchandise and general management for the export sector before moving on to various functions in the domestic retail market spanning operations, buying, merchandising and general management.

Celia started in the Philippine operations of Hong Kong-based Swire & Maclaine Ltd., a subsidiary of London-based John Swire & Sons, before proceeding to handle merchandise management for American department store chain R.H., Macy’s and eventually to general and merchandise management for brand-marketer, Liz Claiborne. The knowledge of international export markets served her well when she sat in the Board of the Foreign Buyers Association of the Philippines (FOBAP) in the past.

My first meeting with her has spun off a public-private partnership of sorts as we move into studying local vegetable dyes and natural fiber development, integrating them into the Great Women Program. Part of this would be to create self-sustaining business in communities where the PTRI could invest small-scale equipment. By increasing production capacities, the local weavers can make “wearables” for their schoolchildren, teachers and government officials. Even if we start here, a local market would begin and we reduce dependence on imports. Whatever is made in excess can be sold at the next town or region.

It’s a small step, this partnership, but a vital one. Bringing technical information and research for use in development programs, and into the hands of weavers and social entrepreneurs may just prove to revitalize the local textile industry. Collaborations by like-minded people, with shared goals, are an exciting venture.